1. Introduction

In the vast landscape of global manufacturing, injection molding machines play a pivotal role, especially in the plastics processing industry. These machines are the cornerstone for producing a wide array of plastic products that permeate every aspect of our daily lives, from the tiniest components in electronics to large - scale automotive parts. As technology advances and global markets evolve, the injection molding machine industry is constantly in a state of flux, presenting both challenges and opportunities. This article delves into the current industry trends and offers insights from ASB Smartrol Import & Export (Guangdong) Co., Ltd., a company at the forefront of this dynamic sector.

2. Global Market Trends of Injection Molding Machines

2.1 Market Expansion

The global injection molding machine market has been on a steady growth trajectory. According to data from Grand View Research, in 2020, the global market size of injection molding machines was approximately 99.4 billion yuan. It is projected to grow at an average annual compound growth rate of 4.5% and reach 141.4 billion yuan by 2028 (Source: Grand View Research, [link to the specific report if available]). This expansion can be attributed to several factors.

The booming demand from emerging economies is a significant driver. Countries in Asia, such as China, India, and Vietnam, are experiencing rapid industrialization and urbanization. Their expanding manufacturing sectors, especially in the automotive, electronics, and consumer goods industries, are fueling the need for injection molding machines. For instance, China has become the world's largest market and production base for injection molding machines, with its production accounting for 65% of the global total in 2019, and this high production level has been maintained in subsequent years (Source: Public data, Huajing Industrial Research Institute).

2.2 Technological Advancements

In recent years, injection molding machines have witnessed remarkable technological progress.

Automation has become a key trend. Modern injection molding machines are equipped with advanced robotic systems for automatic material feeding, mold changing, and product removal. For example, some high - end machines can complete a full production cycle with minimal human intervention. This not only improves production efficiency but also reduces labor costs and human - error - related product defects.

Intelligence is another area of significant development. Through the integration of the Internet of Things (IoT) and artificial intelligence (AI), injection molding machines can now monitor and adjust production parameters in real - time. They can collect data on temperature, pressure, and injection speed, and then use AI algorithms to optimize these parameters for better product quality and production stability. For instance, if the temperature of the mold slightly fluctuates, the intelligent system can automatically adjust the heating or cooling system to maintain the optimal temperature.

Energy - saving technology is also at the forefront of innovation in the injection molding machine industry. With the increasing global emphasis on environmental protection and energy conservation, manufacturers are developing more energy - efficient machines. For example, the adoption of servo - motor - driven systems instead of traditional hydraulic systems can significantly reduce power consumption during the injection and clamping processes. Additionally, some machines use energy - recovery technologies to recycle and reuse the energy generated during the production cycle.

3. ASB Smartrol: Company Introduction

3.1 Establishment and Location

Established in 2023, ASB Smartrol Import & Export (Guangdong) Co., Ltd. is strategically located in Shenzhen, Guangdong, which is renowned as the capital of science and technology in China. This prime location endows the company with unique advantages. Shenzhen's vibrant technological ecosystem, rich pool of engineering talent, and well - developed manufacturing infrastructure create an ideal environment for ASB Smartrol to thrive. The company has quickly emerged as a professional entity dedicated to the research, development, and manufacturing of automation equipment. With a solid 10 - year track record in the industry, ASB Smartrol has continuously pushed the boundaries of innovation, developing and creating high - end automation equipment.

3.2 Global Reach

The company's products have achieved an extensive global reach, being exported to a diverse range of countries and regions. These include Japan, South Korea, Vietnam, Thailand, Indonesia, Singapore, India, Russia, France, Germany, Turkey, Poland, South Africa, the United States, Canada, Australia, and many others. This wide - spread distribution not only demonstrates the high quality and reliability of ASB Smartrol's products but also reflects its ability to meet the diverse needs of international markets.

4. ASB's Featured Product - Mini Desktop Vertical Injection Molding Machine

4.1 Product Overview

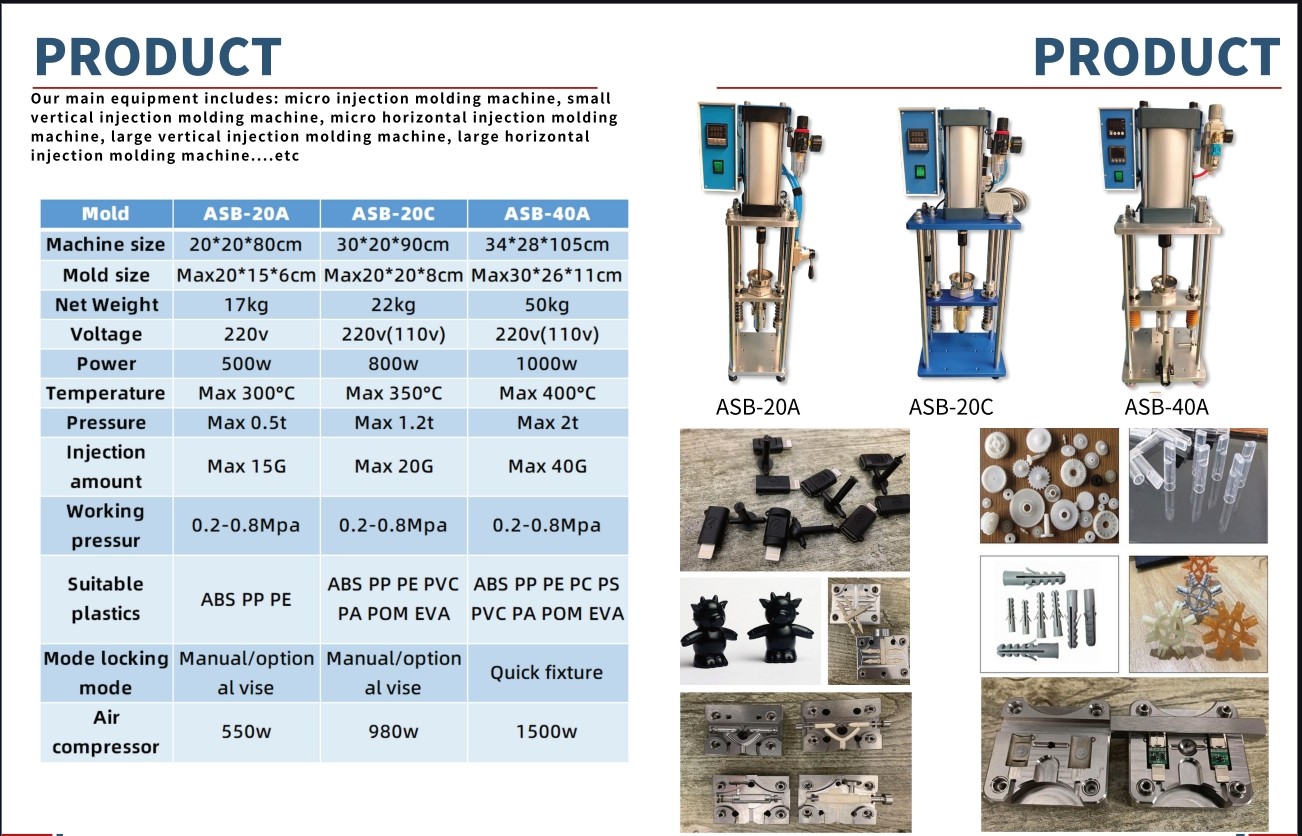

ASB's Mini Desktop Vertical Injection Molding Machine is a game - changer in the field of injection molding. This compact yet powerful machine is designed with precision and functionality in mind. It features a vertical structure, which not only makes it highly space - efficient but also offers unique advantages in operation. For example, the vertical layout allows for easier mold installation and removal, reducing the time and effort required for mold changes.

The machine comes in different models, each with its own set of specifications to meet diverse production needs. The ASB - 20A, for instance, has a machine size of 202080 cm and a net weight of only 17 kg, making it extremely portable. It can handle a maximum injection amount of 15G and is suitable for plastics such as ABS, PP, and PE. The ASB - 40A, on the other hand, is more powerful, with a larger machine size of 3428105 cm and a net weight of 50 kg. It can inject up to 40G of plastic and is compatible with a wider range of plastics, including PC, PS, and PVC, in addition to ABS, PP, and PE.

4.2 Advantages and Competitive Edge

One of the primary advantages of ASB's Mini Desktop Vertical Injection Molding Machine is its performance. It is equipped with advanced technology that ensures high - precision injection molding. The machine can precisely control parameters such as temperature, pressure, and injection speed, resulting in products with excellent dimensional accuracy and surface quality. For example, the temperature control system can maintain a stable temperature within a very narrow range, which is crucial for achieving consistent product quality.

In terms of price, ASB offers a highly competitive pricing strategy. The company aims to provide cost - effective solutions without compromising on quality. Compared to some of its competitors, ASB's machines offer a better balance between price and performance, making them an attractive option for small - to - medium - sized enterprises (SMEs) and startups that are cost - conscious but still require reliable equipment for their production.

ASB also excels in after - sales service. The company offers lifetime maintenance for all of its machines, ensuring that customers can rely on their equipment for the long term. Additionally, ASB provides one - year free replacement of main parts, which gives customers peace of mind. In case of any technical issues, ASB's professional technical team is always ready to provide on - site support and timely solutions, minimizing downtime for customers.

5. ASB's Insights and Strategies in the Industry

5.1 Responding to Market Trends

ASB Smartrol closely monitors the dynamic market trends and adjusts its product development and business strategies accordingly. In response to the growing demand from emerging economies, the company has been actively expanding its market presence in these regions. It has established local sales teams and service centers to better understand the specific needs of customers in different countries and provide prompt support. For example, in Southeast Asian countries like Vietnam and Indonesia, where the manufacturing industry is booming, ASB has tailored its marketing campaigns to target local SMEs, highlighting the cost - effectiveness and reliability of its products.

Regarding technological trends, ASB is committed to integrating the latest technologies into its products. The company is investing heavily in research and development to enhance the automation and intelligence of its injection molding machines. ASB is exploring the application of advanced robotics and IoT technology to create more intelligent and efficient production solutions. This not only enables customers to improve production efficiency but also helps them stay competitive in the global market.

5.2 Quality and Innovation Commitment

Quality is the cornerstone of ASB Smartrol's business philosophy. The company has a strict quality control system in place that spans every stage of the production process, from raw material procurement to the final product inspection. All raw materials are sourced from reliable suppliers and undergo rigorous quality checks to ensure they meet the highest standards. During the manufacturing process, advanced manufacturing equipment and precision machining techniques are employed to guarantee the accuracy and stability of the machines.

Innovation is another key aspect of ASB's success. The company has a dedicated and experienced R & D team composed of professionals with diverse backgrounds in mechanical engineering, electronics, and software development. This multidisciplinary team is constantly exploring new ideas and technologies to drive innovation in the injection molding machine industry. In recent years, ASB's R & D efforts have led to the development of several innovative features in its products, such as improved energy - saving mechanisms and more user - friendly control interfaces. These innovations not only enhance the performance of the machines but also provide customers with a better user experience.

6. Conclusion

In conclusion, the injection molding machine industry is experiencing significant growth and transformation on a global scale. The market expansion, driven by emerging economies and technological advancements, is creating a wealth of opportunities for companies operating in this sector. ASB Smartrol Import & Export (Guangdong) Co., Ltd., with its strategic location, global reach, and commitment to quality and innovation, is well - positioned to thrive in this dynamic environment.

The Mini Desktop Vertical Injection Molding Machine, as a flagship product of ASB, embodies the company's dedication to providing high - performance, cost - effective, and user - friendly solutions. With its unique features and competitive advantages, it has the potential to meet the diverse needs of customers across various industries.

As ASB continues to closely monitor market trends and invest in research and development, the company is expected to introduce more innovative products and services, further strengthening its position in the global injection molding machine market. We encourage readers to explore ASB's product range on our official website at http://asb-machine.com/ and discover how our solutions can add value to your business.